Wooden packaging material are mostly produced from fast growing trees like poplar wood and pine.

For special purposes, e.g. to pack luxury products often wood with a pronounced texture and striking color is used such as birch, lime and maple.

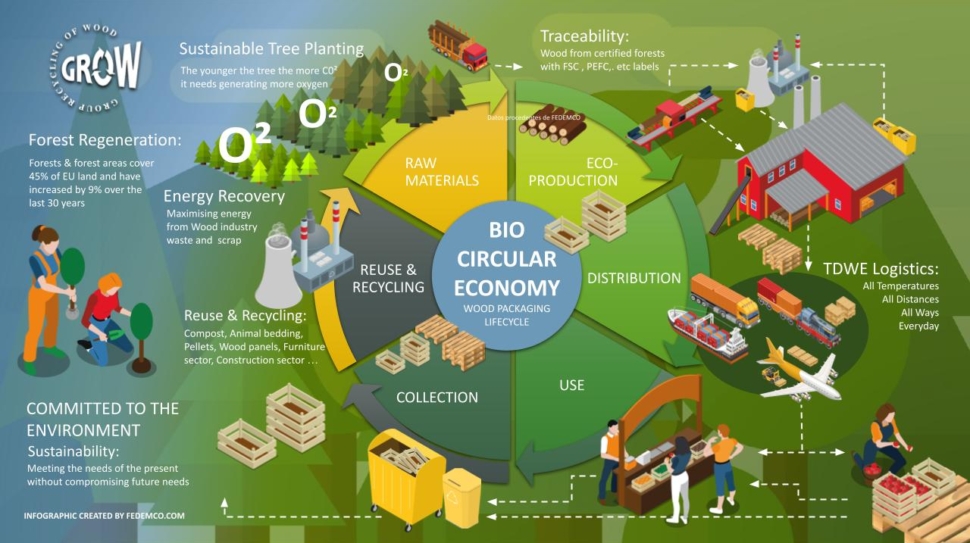

Wooden packing and pallets are produced by purely mechanical processing, so that their is a low energy need and no water is consumed. The primary energy demand for the production of products made of plastic is about 30 times higher than for wood. This primary energy is also mostly from fossil fuels, carbon dioxide content of the atmosphere and thus increase the greenhouse effect. Producers of wooden packaging often use their own wood-waste to produce energy. Both are key benefits of wood in comparison to other packaging materials.

GROW guarantees crate quality and recyclability. Its mark, world wide registered, identifies the crates that have been manufactured of grown wood, poplar plywood and magnetizable staples. Only GROW guaranteed crates are marked with the GROW logo and a license number that identifies the manufacturer, allowing traceability.

RECYCLING

GROW wooden crates, once used, are pressed to make stocking and transport more profitable. Afterwards a single recycling process just involves grinding once eventual non-wood wastes (except from staples) have been removed. At the same time, loose staples or the few still fixed to the chips are separated by means of a electro-magnet.

So, recovery companies transform a waste material in a clean and profitable raw material for the recyclers.

Recyclers can, then, make an eventual second chip grinding to get a new raw material to manufacture other wood sub-products like: chip board, coal bricks, cattle beds, sawdust, organic soil, etc.